Brake Service

Brake inspection and service.

£

00.00

+ Parts

-

Inspection & Safety Assessment

-

Calipers, Pads & Pistons

-

Rotors & Mounting

-

Hydraulic System & Fluid

-

Adjustment & Setup

-

Final Safety Check & Test

Book A Service

Better stopping power.

Drivetrain Service

Drivetrain inspection and service.

£

00.00

+ Parts

-

Inspection & Assessment

-

Chain & Sprocket Service

-

Jackshaft/Reduction Drive

-

Motor Interface & Mounting

-

Rotating Components

-

Replacement Upgrades

Book A Service

Drivetrain safety and performance check.

Wheels Tyres Service

Wheel and tyre inspection and service.

£

00.00

+ Parts

-

Inspection & Assessment

-

Spokes, Truing & Alignment

-

Hub, Axle & Bearings

-

Tyres, Tubes & Mousse

-

Tyre Setup Pressure

-

Final Safety Check Test

Book A Service

Wheel and tyre safety check.

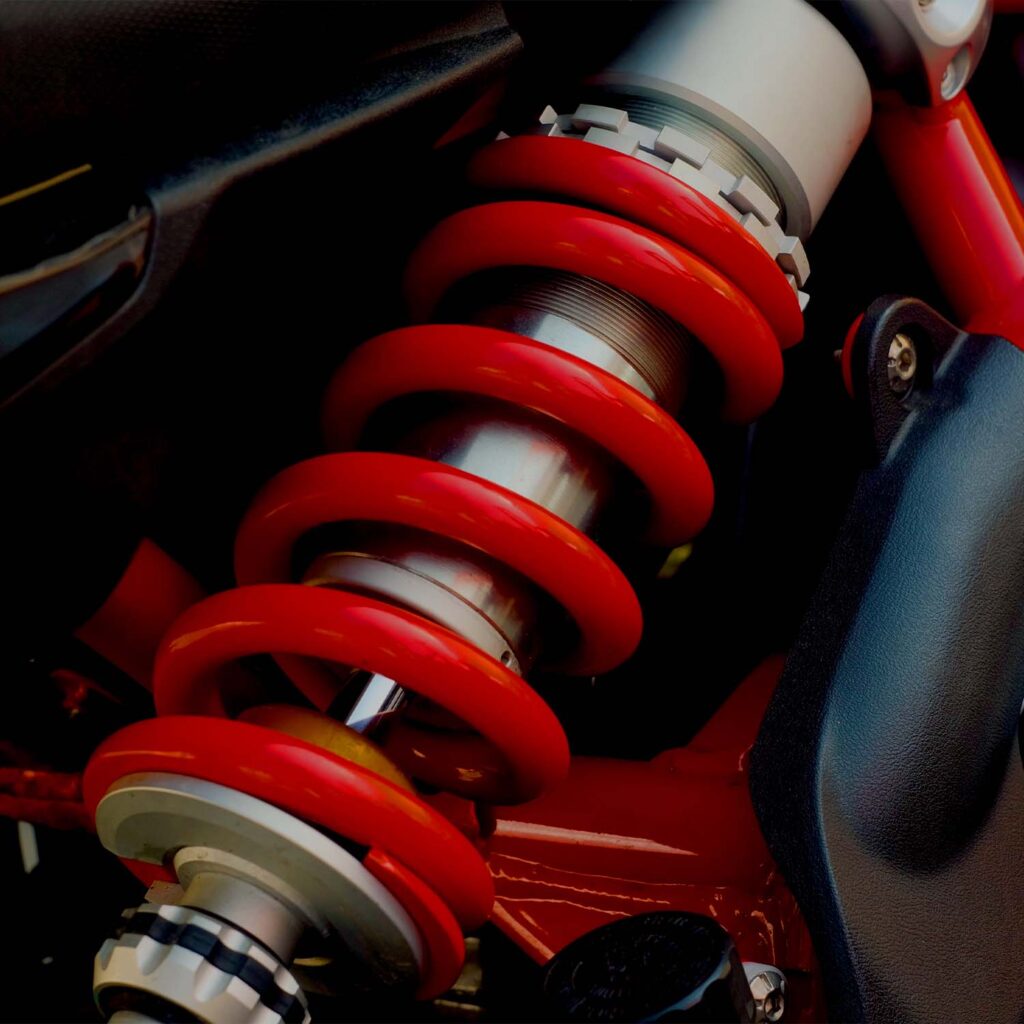

Suspension Service

Suspension inspection and setup service.

£

00.00

+ Parts

-

Inspection & Assessment

-

Fork Service

-

Rear Shock Service

-

Linkage Pivot & Bearings

-

Setup & Adjustment

-

Final Safety Check & Test

Book A Service

Suspension service for control and comfort.

Our eMotocross Brake Service ensures your front and rear braking systems are safe, responsive, and performing at their best. We inspect and service calipers, pads, rotors, hoses, and hydraulic components, check for leaks and wear, refresh brake fluid where required, and correctly adjust and align the system for consistent braking performance. Final safety checks and testing are carried out to give you confidence and control every time you ride.

Inspection & Safety Assessment

Front and rear brake systems inspected for safe operation and performance.

Brake levers inspected for damage, play, pivot wear, and correct return.

Master cylinders inspected for leaks and secure mounting.

Brake hoses inspected for wear, abrasion, heat damage, routing, and securement.

Banjo bolts and fittings inspected for leaks and correct torque.

Callipers, Pads & Pistons

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Rotors & Mounting

Hydraulic Systems & Fluid

Adjustment & Setup

Final Safety Check & Test

Our eMotocross Drivetrain & Final Drive Service focuses on smooth power delivery, reliability, and longevity. We inspect and service the chain, sprockets, jackshaft, bearings, and final drive alignment, ensuring correct tension, lubrication, and torque throughout the system. Worn components are identified early, alignment is corrected to prevent premature wear, and final checks are carried out to ensure quiet, efficient operation and dependable performance on and off the track.

Inspection & Assessment

Drivetrain inspected for wear, damage, alignment, and safe operation.

Front (countershaft) and rear sprockets inspected for tooth wear, hooking, and secure mounting.

Drive chain inspected for stretch, stiff links, corrosion, and correct lubrication.

Final drive alignment checked to ensure straight chain run and even wear.

Noise, vibration, and abnormal drivetrain behaviour assessed.

Chain & Sprocket Service

Drive chain removed where required and cleaned.

Chain inspected for elongation and side-plate wear.

Chain lubricated with appropriate high-load lubricant.

Chain tension adjusted to manufacturer specification.

Front and rear sprocket bolts inspected, cleaned, and torqued.

Chain guide, slider, and guard inspected for wear and security.

Jackshaft / Reduction Drive

Jackshaft bearings inspected for smooth rotation and play.

Jackshaft sprockets inspected for wear and secure mounting.

Reduction drive components inspected for noise and alignment.

Jackshaft fasteners inspected and torqued to specification.

Belt drive systems inspected where fitted (Stark / model dependent).

Motor Interface & Mounting

Motor mounting bolts inspected and torqued.

Motor alignment checked relative to final drive.

Drive output splines inspected where accessible.

Isolation mounts inspected for wear or damage (where applicable).

Bearings & Rotating Components

Front sprocket bearing inspected for play and smooth operation.

Rear wheel drive-side bearing inspected.

Carrier / cush-drive components inspected where fitted.

Axle spacers cleaned and regreased during reassembly.

Replacement & Upgrades

Drive chain replacement.

Front or rear sprocket replacement.

Chain guide or slider replacement.

Jackshaft bearing replacement.

Cush-drive component replacement.

(All parts quoted separately unless specified.)

Final Setup & Safety Check

Final chain tension verified after suspension compression check.

Drive alignment rechecked.

All drivetrain fasteners re-torqued.

Drivetrain run-up test performed.

Test ride completed where safe and permitted.

Our Wheels & Tyres Service ensures your bike rolls straight, grips properly, and performs safely in all conditions. We inspect rims, spokes, hubs, bearings, tyres, and tubes for wear or damage, correct wheel alignment and spoke tension where needed, and set tyre pressures to suit rider weight and terrain. Final safety checks confirm smooth rotation, secure axles, and correct brake alignment for confident, reliable riding.

Inspection & Assessment

Front and rear wheels inspected for damage, cracks, dents, and safe operation.

Rim condition inspected, including bead seat and spoke holes.

Wheel alignment visually assessed for tracking and symmetry.

Spoke tension inspected for looseness, breakage, and uneven loading.

Wheel bearings inspected for smooth rotation, play, and noise.

Spokes, Truing & Alignment

Spokes inspected for damage, corrosion, and correct seating.

Spoke tension adjusted and balanced where required.

Wheel trueness checked and corrected (lateral and radial).

Rim lock position and security inspected and corrected.

(Severely damaged rims or spokes quoted separately.)

Hub, Axle & Bearings

Hub condition inspected for damage or cracking.

Wheel bearings inspected; cleaned and regreased where serviceable.

Sealed bearings inspected and replaced where required (parts charged separately).

Axle shafts removed where required, cleaned, regreased, and reinstalled.

Axle spacers inspected for wear and correct positioning.

Axle nuts torqued to manufacturer specification.

Tyres, Tubes & Mousse

Tyres inspected for wear, cuts, sidewall damage, and correct fit.

Inner tubes inspected for leaks, pinching, or damage.

Heavy-duty tubes or mousse inserts inspected where fitted.

Tyre replacement available.

Tube or mousse replacement available.

Tyres installed and seated correctly with rim locks aligned.

Tyres Setup & Pressure

Tyre pressures set for rider weight, terrain, and riding style.

Rim locks verified for correct engagement and torque.

Valve stems inspected and secured.

Final Safety Check & Test

Wheel rotation checked for smoothness and true running.

Bearing preload and axle security rechecked.

Brake rotor alignment verified after wheel installation.

Short test ride performed where safe and permitted.

Our Suspension Service is designed to restore smooth operation, control, and rider confidence on all terrains. We inspect front forks, rear shock, linkage, and mounting hardware for wear, leaks, and correct movement, servicing external components where required and setting sag, air pressure, and adjusters to suit rider weight and riding style. Final checks ensure smooth travel through the full suspension range, secure fasteners, and balanced handling for consistent, predictable performance.

Inspection & Assessment

Front and rear suspension inspected for damage, leaks, wear, and safe operation.

Fork stanchions inspected for scratches, pitting, wear, and seal condition.

Fork lowers inspected for cracks, damage, and oil residue.

Rear shock inspected for air loss, oil leaks, damping consistency, and mounting condition.

Suspension mounts, spacers, and hardware inspected for wear and play.

Suspension movement checked through full travel for binding or noise.

Fork Service (External / Lower Service)

Fork legs removed where required.

Lower legs cleaned and inspected.

Dust seals and foam rings cleaned and lubricated.

Fork externals cleaned and lubricated.

Fork reassembled and function tested.

⚠️ Does not include internal damper or cartridge rebuild unless quoted separately.

Rear Shock Service (Air Shock)

Rear shock air can removed where applicable.

Air can cleaned, inspected, and lubricated.

Shock mounting hardware cleaned and inspected.

Shock reassembled and pressure restored.

⚠️ Does not include damper rebuild unless quoted separately.

Linkage Pivot & Bearings

Suspension linkage inspected for play, noise, and smooth movement.

Pivot bolts removed where required, cleaned, and regreased.

Linkage and swingarm bearings inspected for wear and contamination.

Bearing replacement available where required (parts charged separately).

All suspension hardware reinstalled and torqued to manufacturer specification.

Setup & Adjustment

Suspension sag measured and set for rider weight and riding style.

Fork air pressure adjusted where applicable.

Rebound and compression clickers set to baseline or rider preference.

Ride height and balance checked front to rear.

Final Safety Check & Test

Full suspension movement rechecked under load.

All suspension fasteners re-torqued.

Short test ride performed where safe and permitted.

Rider feedback adjustments made if required.